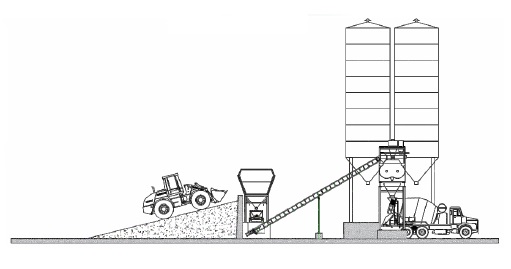

Batching twin shaft

Twin shaft batching plants are produced in three sizes and in different designs. This type of batching has a very simple application. Repairs and maintenance are very low cost and easy to do. It also has a lot of flexibility in design; So that it can be customized easily.

In twin-shaft batching, unlike other two-dimensional batching rotations, the mixing is three-dimensional spiral, which results in faster mixing with less energy and wear.

This mixer is the only mixer suitable for producing RCC coarse-grained concretes.

- Create a three-dimensional rotating motion for fast mixing of materials.

- Create a turbulent mixing zone between two stirring shafts.

- Quickly move all ingredients throughout the mixer while mixing.

- Rapidly creating a uniform concrete mix due to the presence of a turbulent mixing zone.

- Less energy consumption and less wear due to high mixing speed.

- Ability to reduce cement consumption.

- The stirrer arms are mounted in cross-shaped spirals on the shafts.

- The arms move in opposite directions and overlap.

- The paddles are mounted crosswise on the arms.

- The speed of the paddles is different.